Overview

Silica gel vs Molecular sieve

Silica gel and molecular sieve are among the most commonly utilised desiccants in controlling relative humidity of pharmaceuticals, nutraceuticals, and medical devices. This article will outline some key data on these two sorbents, highlighting their usage scenarios and showing key differences. The goal is to inform our customers and hopefully empower them to confidently select the right desiccant for their next product.

What are they?

CILICANTFG white silica gel beads are a form of silicon dioxide with a micro-porous amorphous structure and a maximum loss on drying (LOD) of 2%. The pores have sizes ranging from 3 – 60 Å and interconnect to form a large surface area for water uptake. CILICANTFG silica gel utilises both adsorption and capillary condensation to control free moisture, retaining up to 40% of its weight in water.

Cilicant molecular sieve is a synthetic zeolite with excellent moisture adsorption properties. With an aggressive nature, Cilicant molecular sieve is fast acting at low relative humidity (RH). It features uniform crystalline pores and empty adsorption cavities. Cilicant molecular sieve has an internal surface area for adsorption that equates to 50% of the total volume of its crystals.

Why use them?

Both silica gel and molecular sieve play a critical role in the pharmaceutical industry. These desiccants protect drugs, active pharmaceutical ingredients (APIs), and medical devices from the harmful effects of hydrolytic degradation triggered by unbound water in packaging headspace. When manufacturing moisture sensitive pharmaceutical products, it is vital to select a desiccant that will extend shelf-life without compromising safety and efficacy.

Differentiators

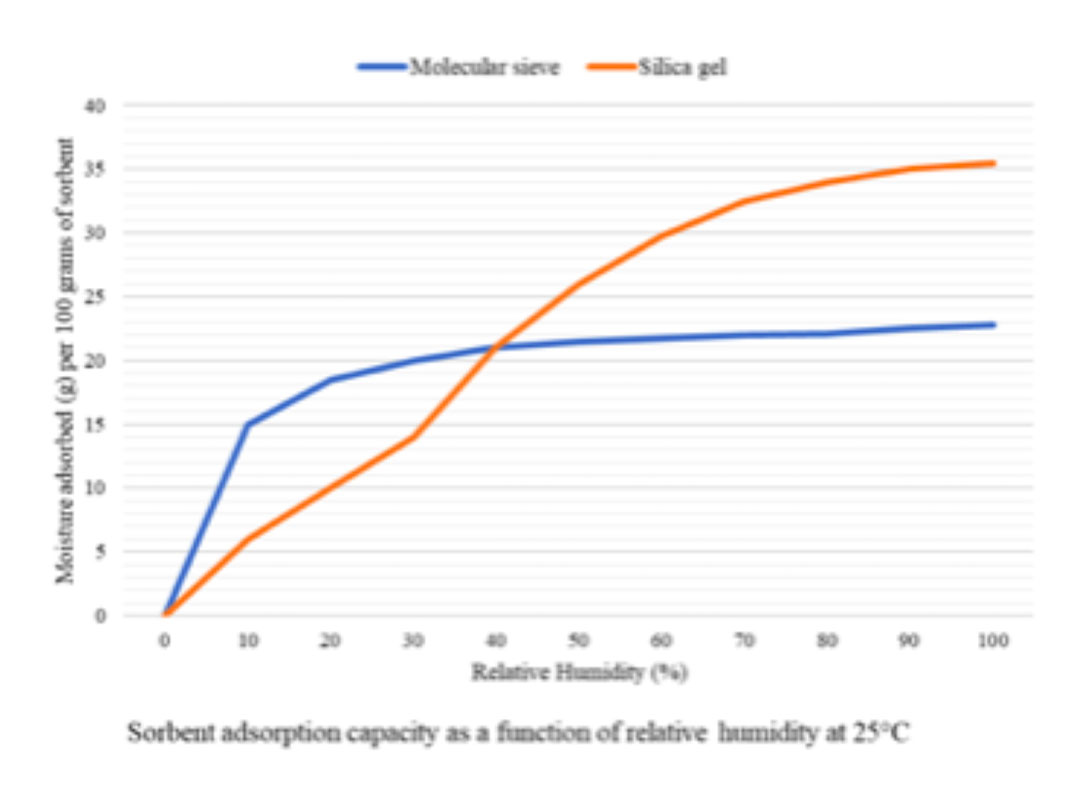

The moisture adsorption properties of molecular sieve and silica gel differ at a few key performance criteria. While molecular sieve has an excellent adsorptive capacity at low humidity levels, silica gel tends to perform poorly at the same. Both, however, have similar moisture retention capacities at room temperature (25°C) and 40% relative humidity.

Molecular sieve has a higher rate of adsorption, resulting in faster moisture removal when compared with similar quantities of silica gel. Free moisture fits into the uniform pores of molecular sieve at a higher rate than in silica gel. This translates to faster attainment of specified levels of relative humidity in pharmaceutical packaging when utilising molecular sieve.

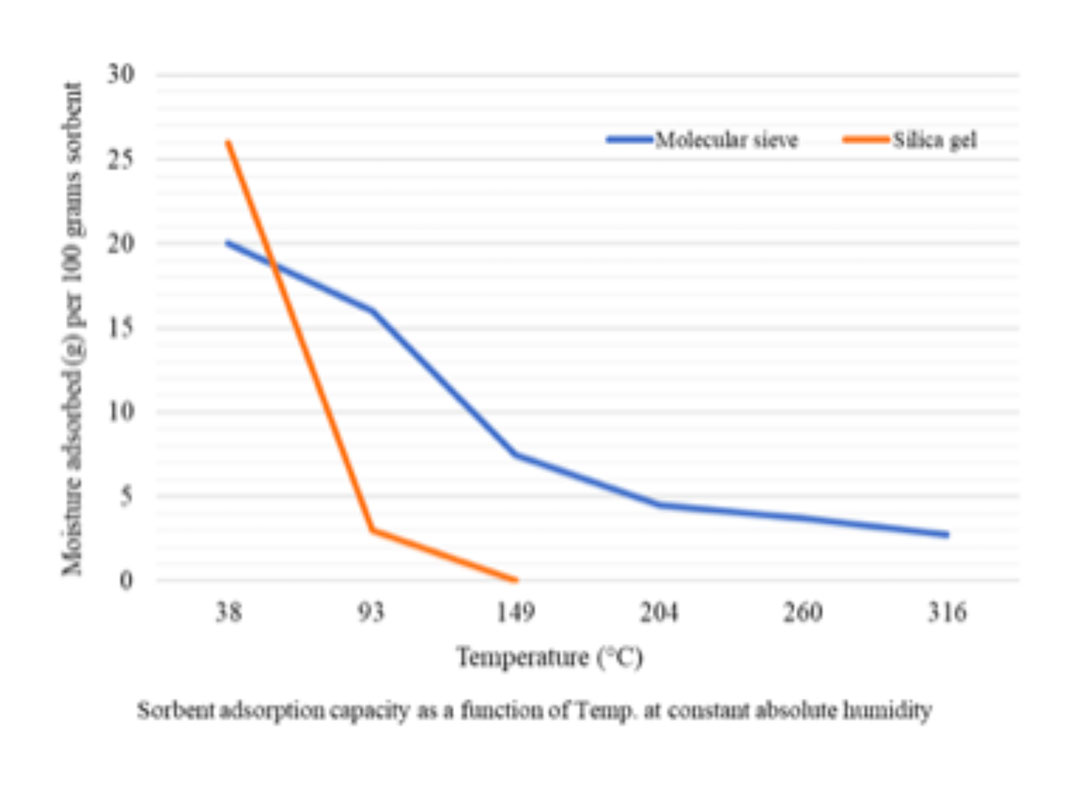

The properties of both desiccants are affected by temperature increases in dissimilar ways. At elevated temperatures, the adsorptive capacity of silica gel wanes and it may give up moisture into the packaging. Molecular sieve, on the other hand, has excellent moisture retention properties at higher temperatures because of a uniform structure that strongly binds water even at higher temperatures.

| Property | Silica Gel | Molecular Sieve |

| Structure | Amorphous with many irregular pores | Defined, with uniform crystalline pores |

| Rate of adsorption | Good | Excellent |

| Moisture retention capacity | High, although it lessens with increase in temperature | High, and stays good at elevated temperatures |

| Adsorption capacity (RH<40%) | Outperforms molecular sieve when RH increases above 40% at 25°C | Remains mostly constant when RH increases above 40% at 25°C |

| Adsorption capacity (RH<40%) | Lower than molecular sieve | Significantly higher than silica gel |

Which one should I choose?

Silica gel would be a great desiccant to use in products with stable storage temperatures and high relative humidity. With an inert, non-toxic, and stable nature silica gel is a popular desiccant choice in many pharmaceutical products. Caution must be exercised to avoid large temperature variations as these may affect the performance of silica gel.

With its aggressive and rapid water adsorption properties, molecular sieve would perform better in products that require quick protection from moisture degradation. Molecular sieve is stable over large temperature ranges and has higher moisture retention properties. Caution must be exercised when selecting the proper dosage for use in products with specific RH requirements.

Do desiccants have side effects on pharmaceuticals?

The humidity of the packaging environment should be optimised for each product and selective use of desiccants applied. Without optimisation, the relative humidity of the packaging environment may go out of range resulting in instability of the physical and chemical properties of the API and excipients. Such optimisation will inform the choice and quantity of desiccant to use to prevent under-desiccation or over-desiccation of pharmaceuticals.

Read More …

When less-than-optimal quantities of desiccant are utilised, this may result in insufficient removal of excess humidity from the packaging headspace. Consequently, a domino effect leading to the degradation of pharmaceuticals may ensue. Solid forms might deliquesce in the presence of free moisture exceeding their critical relative humidity. The hardness of uncoated tablets decreases along with an increase in friability. Gelatinous capsules tend to become sticky and may adhere to each other. Optimal use of silica gel and molecular sieves, among other desiccants, would limit many of the negative effects of under-desiccation.

On the contrary, overapplication of desiccants results in sub-optimal RH in the packaging environment. Hard gelatine capsules become brittle and crack when the RH drops below 30%. In the presence of unregulated amounts of desiccants, static charges build-up in the packaging environment drying out medications and potentially limiting the efficiency of the API and any excipients. In ambient conditions, over-desiccation is of greater concern with molecular sieves because of their aggressive nature. Equilibrating the RH of both the product and packaging environment would minimise the effects over-desiccation in the product.

Read Less …

The Cilicant advantage

Cilicant desiccants can be safely used to control relative humidity in a large variety of pharmaceuticals, nutraceuticals, and medical devices, extending their shelf life. Both CILICANTFG silica gel and Cilicant molecular sieve are manufactured with particular care to ensure they protect moisture sensitive products from degradation without affecting performance. Customers may contact us to find out more about the CILICANTFG silica gel sachets and our other products.